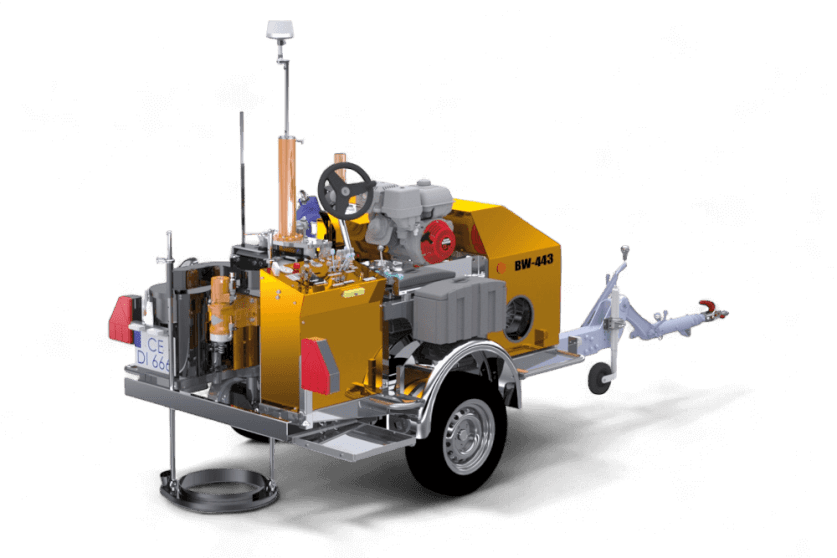

The BW-443 self-propelled core drilling machine is the ideal solution for self-sufficient and mobile core drilling - without any external water or power supply. With a trailer coupling and 100 km/h approval, it is ideally equipped for Swiss road traffic. The fold-out drive wheel enables simple and independent movement directly on the construction site.

The fully hydraulically operated BW-443 drill trailer was specially developed for removing drill cores from asphalt and concrete surfaces, drilling openings for crash barriers and for use on airfields to drill stepped holes for underfloor lighting.

In contrast to the CEDIMA BW-300 and BW-400 core drills, this model is already equipped with collision protection, a horizontally adjustable drill head and an integrated extraction unit as standard. The BW-443 also has a combined diesel and petrol engine.

This powerful, self-propelled core drill is the ideal choice for precise drilling under the toughest conditions - independent, efficient and reliable.

All advantages at a glance:

- Self-sufficient working: No external power or water connection required

- 100 km/h approval: CH-compliant for road transport)

- Demanding drill holes: Ideal for precise core and step drilling in asphalt or concrete

- Standard equipment: With collision protection, suction and horizontally adjustable drill head

- Self-propelled: Can be maneuvered directly on the construction site thanks to fold-out drive wheel

- High mobility: Height-adjustable drawbar with interchangeable ball or ring eye coupling

- Durable & robust: For daily, intensive use in civil engineering and road construction

Areas of application:

- Road construction and infrastructure projects (e.g. drilling holes for crash barriers)

- Airport construction and underfloor lighting

- Material analysis and damage assessment

RUBAG standard equipment:

- Drill feed - hydraulic lifting and lowering of the drilling platform

- Horizontal drill head adjustment ± 100 mm

- Fold-out drive wheel

- Suction device

- Collision protection

- Damper for comfortable driving

- Height-adjustable drawbar with interchangeable ball head and ring eye coupling

- Al-Ko AAA axle

CEDIMA drill trucks are characterized by high reliability, maximum power utilization, easy handling and high operating comfort. The drive unit and drill shaft speed have been designed to provide optimum conditions for drilling with CEDIMA diamond core bits.